26/11/2025 · ECOSYSTEM

"Building the Workforce for a Growing Additive Manufacturing Industry" by EOS

28/10/2025 · ANNOUNCEMENT

Stratasys Highlights Cross-Sector AM Adoption

07/09/2025 · ANNOUNCEMENT

1st Global AM Hubs Summit Barcelona

Get tickets

At the upcoming Global AM Hubs Summit 2025 in Barcelona, one of the most promising highlights will be the participation of 3Deus Dynamics , a French Deep Tech startup that is reshaping the boundaries of AM through its groundbreaking Dynamic Molding process.

Founded in Lyon in 2020 by Julien BARTHES , together with Edwin-Joffrey COURTIAL and Christophe Marquette , 3Deus Dynamics has quickly positioned itself at the forefront of silicone additive manufacturing. Its patented technology, born from research at the ICBMS in Lyon and supported by Pulsalys, Elkem and the French National Research Agency, combines principles of AM and molding to create a new paradigm in 3D printing.

«Joining the Global AM Hubs Summit in DFactory Barcelona is highly relevant for us: it is a unique opportunity to showcase our disruptive approach, strenghthen European collaborations, and take part in shaping the future of additive manufacturing alongside leading hubs, institutions, and industry players.» - Julien BARTHES , CEO of 3Deus Dynamics

For 3Deus Dynamics, this stage is far more than an exhibition platform. It is a strategic arena where the company will:

In addition, the company emphasizes its admiration for the strong momentum of technological development in Spain, making the Global AM Hubs Summit an ideal platform to reinforce ties and pursue new cross-border collaborations.

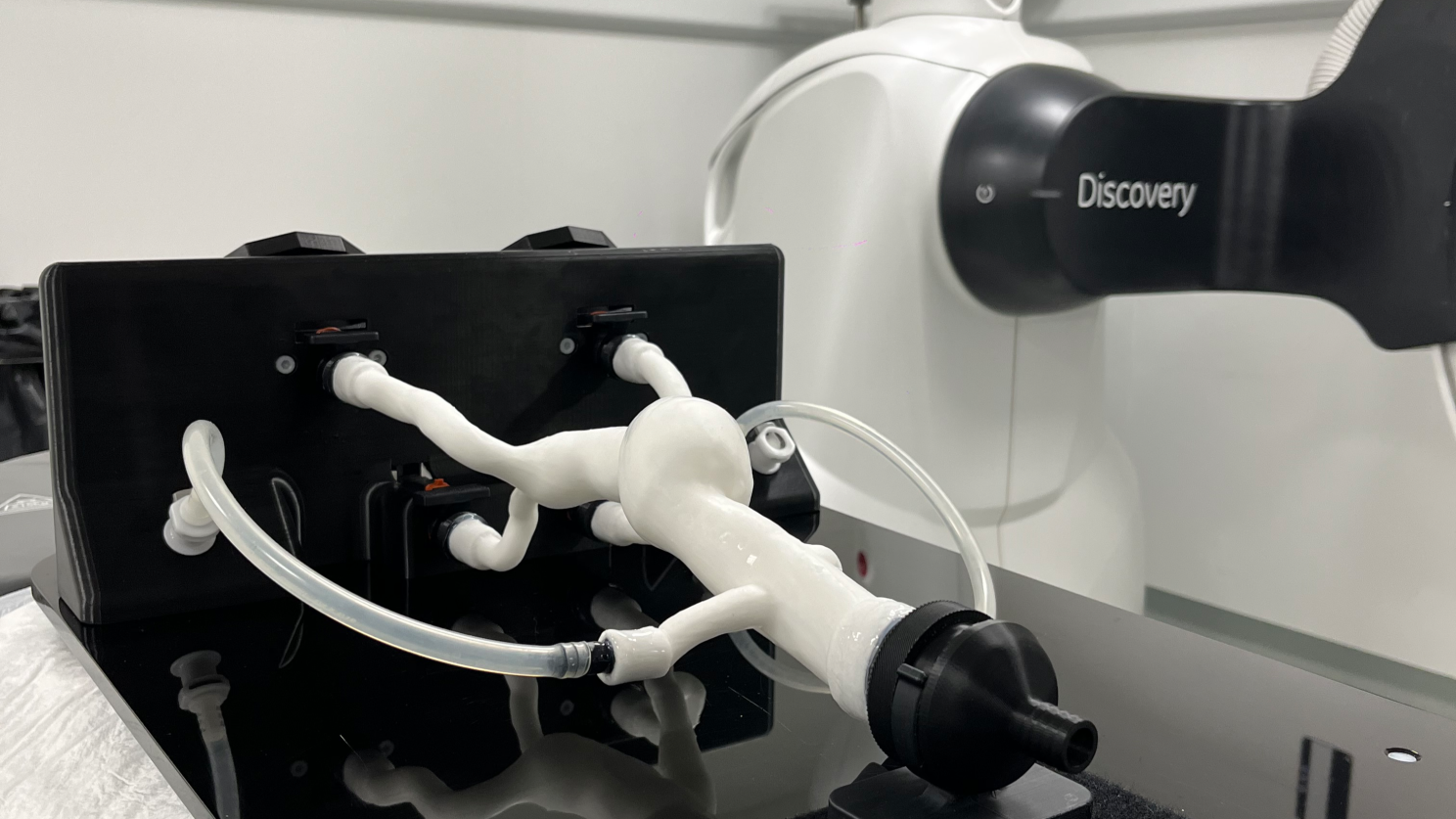

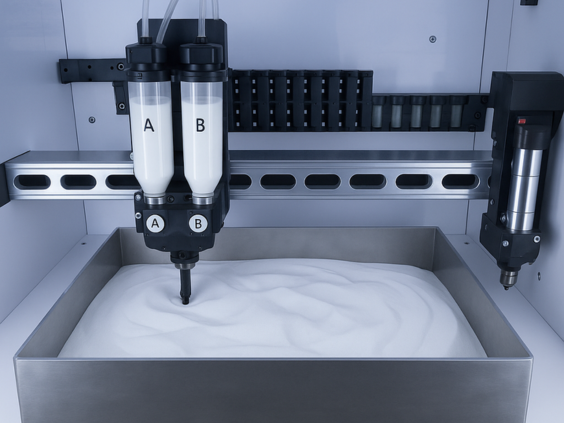

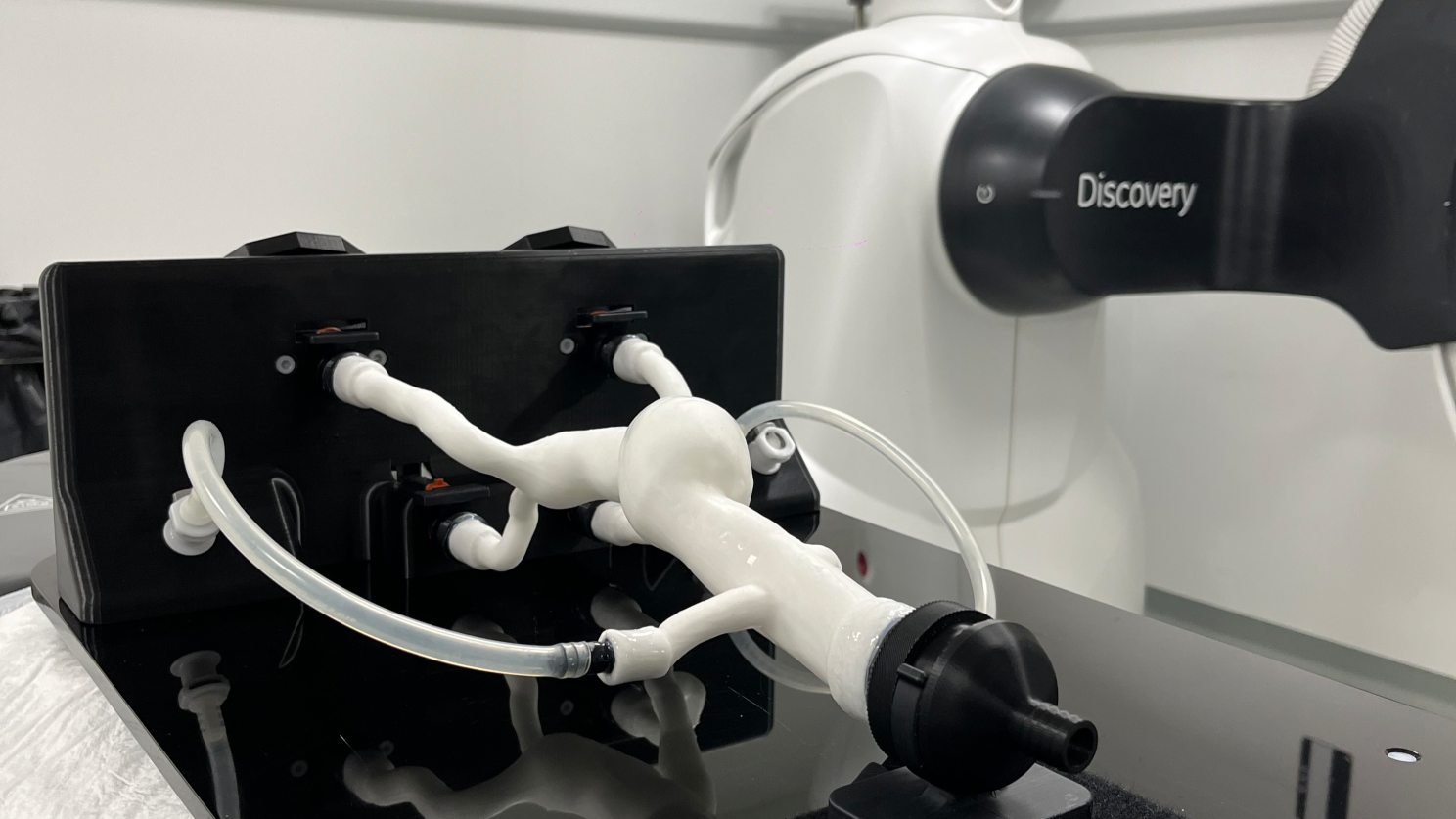

At the heart of 3Deus Dynamics 's finished products lies a patented hybrid process that combines additive manufacturing with molding in a unique "zero-gravity" approach. Using a granular medium as a dynamic mold, the process allows viscoelastic materials - including silicones, elastomers, thermoplastics - to be shaped without altering intrinsic properties. The environmentally low-impact innovation addresses several challenges in 3D printing:

By merging flexibility, precision, and sustainability, Dynamic Molding is opening new opportunities across industries. Its impact already extends from life-like surgical models that improve training and patient-specific care, to high-performance aerospace seals offering extreme fire resistance or high electromagnetic shielding.

3Deus Dynamics transforms its patented process into value-added manufacturing services and finished parts, defining new standards for demanding industries:

Healthcare - Setting a new gold standard in medical simulation. With its Dynamic Molding process, 3Deus Dynamics produces ultra-realistic silicone anatomical models, tailored for different training and testing needs:

Aerospace & Defence - Next generation sealing solutions. In parallel, 3Deus Dynamics develops high-performance sealing products for demanding aerospace and defence applications:

26/11/2025 · ECOSYSTEM

28/10/2025 · ANNOUNCEMENT

07/09/2025 · ANNOUNCEMENT